Other Complete Carbon Fiber Line Equipment

Sizing Systems

Litzler supplies engineered sizing stations as part of a Complete Carbon Fiber Line or for upgrading existing machines. Special sizing solutions are applied to the carbon fiber for downstream processing.

- Custom heated sizing tanks with lift systems

- Special large diameter dip rolls to ensure proper tow tracking and solution residence time

- Precision squeeze rollers are used to evenly coat the tow

- Conduction drying or non-contact hot air drying

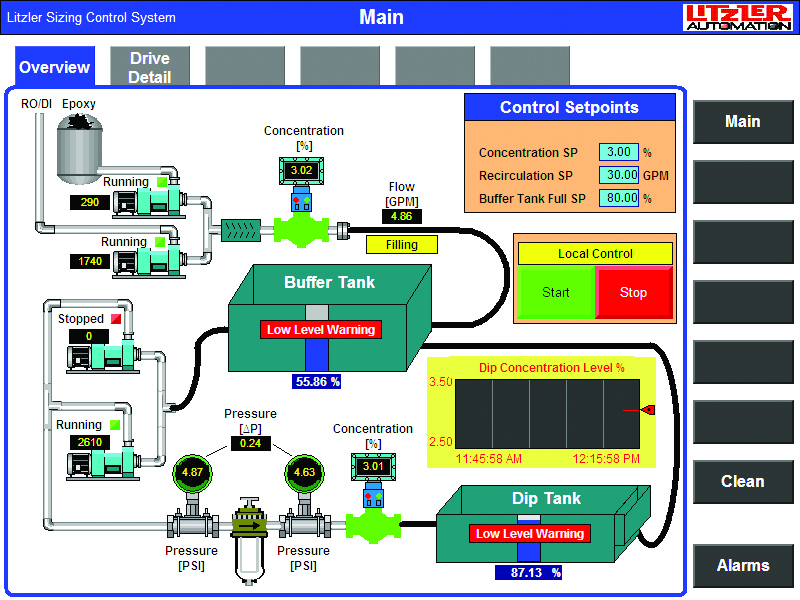

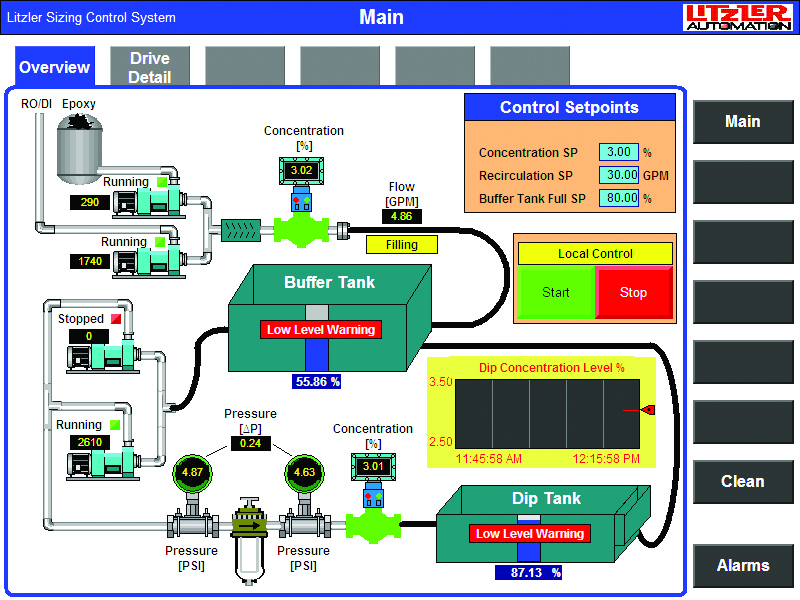

Sizing Concentration Systems

Sizing Systems require precise control over chemicals and mixture concentration levels. Litzler offers a variety of options, depending on the need:

- Mixing systems, including variable speed peristaltic pumps, concentration monitors, filters, stainless steel piping and PLC control with color touchscreen

- Proprietary sizing tanks and buffer tanks including weir overflow level control

- Pre-piped and tested systems feature PLC and recipe control through Litzler Automation

- Epoxy and deionized water solutions are constantly monitored to maintain the specified mixture

Sizing Dryers

Water-based sizing requires special Sizing Dryers, which Litzler provides in multiple configurations:

- Conduction dryers with large diameter steam or hot water drums

- Hot air convection dryers for non-contact drying

- High-efficiency impingement designs

- Gas, electric or steam heat

- Litzler Automation Control Systems

Surface Treatment

Surface Treatment is required to etch the fiber after carbonization. Litzler customizes the Surface Treatment for every application.

- Stainless steel solution bath (electrically isolated)

- Anode rollers/special rollers

- Solution circulation systems

- Conductivity control

- Conduction dryers with steam or hot water drums

- Heavy-duty rectifiers with adjustable current control

- Litzler Automation Control Systems